Steaming bags are a convenient and affordable way to cook your food at home. These flexible plastic bag contain already cooked or partially cooked ingredients, which you can seal up for later use without any refrigeration!

Retort pouches as a daily pouch were widely used in our kitchen life. It’s a good assistant for us. For those a thousand types of retort pouches, do you really know what exactly are retort pouches? Or how’s work for our life? What’s special of the material and how’s the standard of those food packaging?

In this article, we’ll show you the answer! Let’s get to know more!

Made from heat-resistant laminated plastic, retort pouches are semi-rigid, flexible packages. Food products like soups, pasta, rice, sauces, and cook-in-a-bag meals are sealed and sterilized in these pouches with a maximum temperature of 121°C. Thus, they are the go-to packaging for convenience, processed, and pre-packaged food.

The history of retort pouches

The idea for retort pouches was promoted by the US army in 1950 and the research continued through 1960. It was finally invented by United States Army Natick R&D Command, Reynolds Metals Company, and Continental Flexible Packaging and was first introduced in Italy. These companies received the Food Technology Industrial Achievement Award for their invention in 1978.

The entrance of new packaging mediums is changing the game for food manufacturers, and retailers alike. The stable vertical package offers an easy way to get your product from point A all the way through sterile storage without any risk or worry about it becoming damaged along its journey.

We have never seen so much packaging innovation in such a short period of time. Pet food manufacturers, seafood manufacturers, and other food manufacturers have begun to consider this new way of customizing food packaging to make their products more attractive to consumers. Cookable pouches offer many advantages over traditional tin cans.

At first, the retort pouches were not accepted by many people. However, as manufacturers and companies realized their benefits over time they became more common in packaging products for sale because of how well-made these bags are to protect your food during transport or storage.

Inside of retort pouches

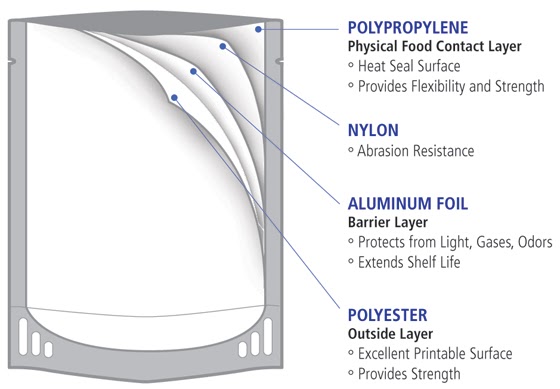

Steaming bags are a demanding package consisting of three layers that can be processed like cans, and they’re shelf-stable too! When we wax poet about how well retort pouches to package it is because its internal structural composition has the sturdiness metal tins while protecting your nutrient value inside.Specifically, each pouch consists of four layers as shown in the image below.

- The first layer is propylene which acts as a heat seal surface and provides strength and flexibility.

- The next layer which is the nylon layer protects from abrasion.

- The aluminum layer not only protects from lights, gases, and odor but also extends the product’s shelf life.

- The final polyester layer provides excellent strength and is very easy to print on.

The materials that go into the packaging of retort pouches are FDA approved and undergo sterilization processes which increase the durability of the packaging.

Material of retort pouches

The structure of the high-temperature resistant cooking bag has two layers, three layers, four layers, and even more.

Among them, the second layer is a transparent plastic/mold, such as PET / CPP or OPA / CPP.

The three layers are transparent plastic/mold, such as PET / OPA / CPP, and opaque types containing aluminum foil, such as PET / AL / CPP, OPP / AL / CPP.

The four layers are opaque PET / AL / OPA / CPP with aluminum foil. This structure is a puncture-resistant, reinforced, large-capacity packaging bag. The OPA should be reasonable between AL and CPP.

The more layers are mainly The inner layer does not use pure CPP film, but uses multi-layer co-extruded film, such as PA / EVOH / PP, PA / PVA / PP co-extruded film plus PET or aluminum foil to form a composite with more layers, but its quantity Not much.

From a functional point of view, the four-layer structure PET / AL / OPA / CPP bag containing aluminum foil can completely meet the requirements of all cooked food.

For these materials used in cooking bags, it is necessary to introduce their properties and functions. In order to ensure the quality of cooking bags, specific requirements should also be put forward.

1. Polyester film PET, also known as biaxial (or biaxial) stretch polyester film

The high melting point and resistance to gas make it perfect for cooking bags. The 12-micron thickness also gives the material an advantage when printing or binding with other materials because of its transparency, strength (from molecular weight), durability etc., all in one package!

When PET is used as the outer layer material and other heat-sealable materials (CPP, PE, etc.) are compounded to heat-seal bags, even if the temperature is as high as 220 ° C, it will not melt and deform, and will not stick to the knife. Bag making. At present, there are many PET film production suppliers in China. Most PET films can meet the high-temperature cooking of 120 ~ 128 ℃, and even meet the high-temperature cooking of 135 ℃. However, there are also some PET films with thermal shrinkage. Large, the problem of deformation after high-temperature cooking. Therefore, when choosing PET for high-temperature cooking, be sure to choose a product with a small heat shrinkage ratio, and then use it with confidence.

2. Aluminum foil AL

Aluminum foil is a metal material. Most of the soft aluminum foils with a thickness of 9 μm are used on the cooking bags. Airtight (O2, N2, CO2, etc.), opaque, and extremely high heat resistance and oil resistance, so the composite bag made of aluminum foil has a full seal (like tinplate cans), high security It has excellent properties such as oil resistance and high-temperature resistance. It is the highest-grade composite flexible packaging material.

3.Cast polypropylene CPP

The most popular material for cooking bag packaging is polypropylene, which has an interior layer of unstretched cast film. The thickness varies depending on what you are using it for; however, 70-80 microns will do just fine when storing food or heating items ensuring their safety from heat damage.

High-temperature retort pouches – as one of the most commonly used cooking bags, its trial materials and standards may be higher. Do you know the high-temperature retort pouches?

What’s High- temperature retort pouches?

Many consumers may not be aware that the product in a steaming bag is cooked in a sealed bag. This revolutionary packaging process is called steaming and is the same process as autoclaving, the ability to heat and sterilize the package and contents.

The high-temperature cooking bag is a kind of composite plastic film bag that can be heated. It has the advantages of both a canned container and a boiling water-resistant plastic bag. Sterilized and heated, ready to eat. After more than ten years of use, it is an ideal sales packaging container.

Types of High-temperature retort pouches

Classification by structure:

Class A: PA / CPP, PET / CPP. Amount of water vapor transmission: ≤15g / (m㈠4h); Amount of oxygen transmission: ≤120cm / (m2㈠4h0.1HPa).

Type B: PA / AL / CPP, PET / AL / CPP. Water vapor transmission rate: ≤0.5g / (m (4h); oxygen transmission volume: ≤0.5cm / (m㈠4h0.1MPa).

Type C: PET / PA / AL / CPP, PET / AL / PA / CPP. Amount of water vapor transmission: ≤0.5g / (m㈠4h); Amount of oxygen transmission: ≤0.5cm / (m㈠4h0.1MPa).

Classified by cooking temperature

When the relative pressure is 110 psi, the corresponding temperature is l15cC; the shelf life is about 3 months.

When the relative pressure is Ps 1 15 psi, the corresponding temperature is 121cC; the shelf life is about 6 months.

When the relative pressure is PS 1 20 psi, the corresponding temperature is 126cC; the shelf life is about 12 months (transparent bag).

When the relative pressure is PS1 30 psi, the corresponding temperature is 135cC; the shelf life is about 24 months (aluminum foil bag).

Of course, the shelf life has a lot to do with the barrier properties of the cooking bag and the type of food.

However, those kinds of retort pouches are commonly used in our life right now while they do help to save the day! Let’s see:

Well-designed

The sturdy packaging of these pouches protects them during transportation, making them both cost-effective and temperature resistant. They can withstand variations up to 250 degrees Fahrenheit without leakage!

Resource-efficient

Retort pouches utilize just 5% of the packaging material and at the same time improve the food texture, flavor, and aroma. Also, the energy that goes into the production of these pouches is much less than what goes into making metal, paper, or glass packages. They are made with high-quality materials and are environment-friendly.

Space-efficient

Retort pouches can stand upright on the shelves and this helps in maintaining the food composition inside. They are also flat and hence take up very little space on the shelf as well as in the shopping bags.

Combinedly, all of the above advantages serve to make retort pouches the go-to packaging, especially in the food and beverage industry.

Conclusion:

According to the introduction, the retort pouches are different according to the material and the number of layers. During use, you can also choose different specifications and types of cooking bags according to different cooking environments and foods.

It is undeniable that retort pouches are indeed closely related to our lives. In order to meet the current public’s pursuit of environmental protection concepts, many manufacturers have also started to develop green retort pouches.

PrimePac is a manufacturer specializing in packaging production. It pays attention to every detail from material selection to production. Technological innovation is productivity and it is your trusted cooking bag manufacturer.

About Primepac

Primepac is UK’s number 1 choice for plain and custom-printed high-quality packaging.

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in the UK to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.