Beverage and food packaging materials are the industries that waste the most energy and resources. The annual production demand for packaging materials is as high as 67 million tons, which not only consumes energy resources but poses a serious threat to the ecological environment. Biodegradable packaging is a great way to reduce our harmful impact on Earth.

Degradable plastic refers to plastics with certain additives (such as starch, modified starch or other cellulose, photosensitizers, degradants, etc.), which have lower stability and are more easily degraded in the natural environment. The use of degradable plastic can help alleviate environmental problems by reducing waste.

After this article gives an overview of the biodegradable packaging market, it mainly explains the types of degradable packaging materials and summarizes the factors driving this market development, and then describes the current market size and forecasts of the market’s future. Finally, it points out various challenges encountered by the degradable packaging industry in the development process.

Market review of biodegradable packaging

Companies around the world are adopting sustainable packaging solutions, including the use of biodegradable and recyclable paper. According to statistics, paper packaging solutions will dominate the market in 2022, so the use of paper in packaging materials will increase. To gain a larger share of the market, many companies that provide paper packaging solutions have started focusing on biodegradable products. Industry leaders are working hard to create complete and fully-biological packages for all your needs so you can be sure not just about quality but also sustainability!

Compared to end-user consumers, the demand for these packaging solutions is considered high in the industry because it eliminates the need for attractive packaging in industrial solutions. However, recycling remains one of the main trends observed in the industry.

Although paper products are biodegradable, the process has been determined to be inconsistent in landfills due to the presence of external elements. The impact of the landfill is attracting the attention of municipalities. Governments and organizations are promoting the recycling of disposable landfills, and biodegradable packaging is highly recyclable.

The ability to use biodegradable materials in the packaging industry is increasing due to the growing demand for recyclable materials in end-use industries such as personal and home care, food, and beverage, and pharmaceuticals. which is driving a biodegradable packaging trend that’s sure to continue. In particular, in the food packaging industry, biodegradable packaging materials have been widely used to promote green living around the world, essentially by reducing waste. In addition, in recent decades, continuous efforts to adopt sustainability in sustainable development have led to widespread demand for such packaging materials.

Biodegradable packaging material types

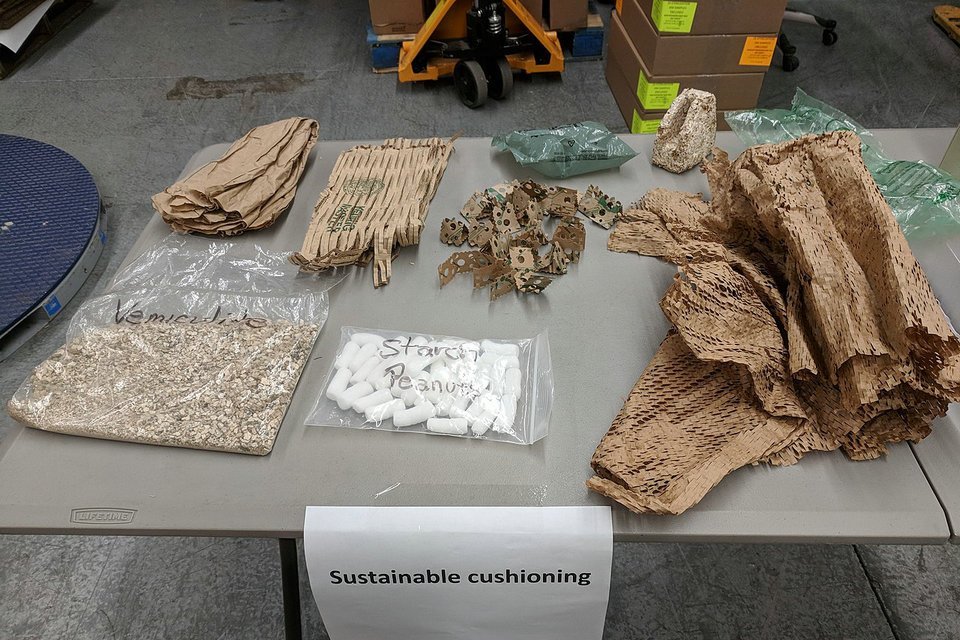

Green packaging materials mainly refer to materials that have good use performance, or function, have little pollution to the ecological environment, are easily degradable,have high recycling rates, or can be effectively recycled in the environment without causing harm to human bodies.

The biodegradable packaging market was valued at $3.37 billion in 2022 and is expected to reach a market value of $10.3 billion by 2024, with a CAGR of 20.3% during the forecast period from 2022 to 2030.

Biodegradable packaging has been widely used in the packaging industry because of its ecological friendliness. With the rising price of crude oil and issues related to petroleum-based plastics, the concept of using biodegradable plastics as an alternative to various applications such as FMCG, hospital, and manufacturing is increasing, which is driving the development of the market.

The key point of green packaging is whether the packaging materials are reusable and degradable. Biodegradable materials such as bioplastics and paper are widely used in the packaging industry because of their sustainable properties, appearance, and properties.

1.Driven by sustainable development

Degradable materials have less impact on the environment, meet the requirements of sustainable development, and can effectively solve problems such as environmental crises. Therefore, the demand is constantly growing, and biodegradable packaging products are increasingly used in various industries. Since most of the materials used in this package are natural and can be degraded without a catalyst, this package has a wide range of applications in the food and beverage industry.

Companies are taking steps to reduce their environmental impact. Such as Unilever and P & G have promised to switch to natural packaging solutions and reduce their ecological footprint (mainly carbon emissions) by 50%, which is one of the factors driving the use of biodegradable packaging in various industries. More and more innovations, such as automatic and smart packaging solutions in the industry, are being extended to end products.

2. Consumer preference driven

One of the key factors contributing to the growth of this market is the consumer’s increasing focus on environmentally friendly packaging. As consumers’ focus shifts to a healthier life, consumers are more inclined to choose environmentally friendly plastic bags and environmentally friendly food packaging bags, and their demand for natural, environmentally friendly and green products is also increasing. This shift in consumer behavior is forcing major plastics manufacturers and packaging manufacturers to continually explore the possibilities for the application of biodegradable polymer materials.

3. Legal supervision

In an effort to protect our environment, many countries have strict regulations on waste and the promotion of biodegradable packaging materials. promote the use of biodegradable packaging materials. It is reported that developed countries and regions in Europe, the United States, Japan, and other countries have successively formulated and introduced relevant regulations to restrict the use of non-degradable plastics through measures such as local bans, restrictions, and compulsory collection.

Among them, France introduced a policy in 2005: that all disposable plastic bags must be biodegradable after 2010, it can be seen that non-environment-friendly packaging materials will continue to run into obstacles in the future development market. Correspondingly, environmentally friendly packaging materials will usher in a golden period of development. These materials are usually made from renewable raw materials such as starch and cellulose. Biodegradable plastic can be decomposed into compounds by the enzymatic action of microorganisms, into CO2, methane, and water.

Market size and forecast of biodegradable packaging

Data show that the global packaging market’s demand for degradable plastics will reach 9.45 million tons in 2023, and the market size will reach 113.55 billion US dollars.

The market for degradable plastic packaging is huge, and the demand for food packaging accounts for more than 70% of the market for degradable plastic packaging, which is self-evident. Relevant research also emphasizes the latest development trends. Under the new situation, “green packaging” will be more and more widely used in the logistics industry.

This requires logistics companies that provide packaging services to carry out green packaging transformation, including the use of environmentally friendly materials. Improve material utilization, design folding packaging to reduce empty load rate, establish a packaging reuse system, etc .; promote the production department to adopt packaging that is as simple as possible and made of degradable materials; in the circulation process, various measures should be taken realize the rationalization and modernization of packaging.

A previous IHS Markit report showed that the market value is expected to reach 1.7 billion US dollars by 2023. The report highlights the application of these biodegradable material solutions in various regions and industries.

Challenges of biodegradable packaging

At present, there are still some problems in the development and application of biodegradable polymers:

# Due to issues such as corporate interests, the popularity of degradable plastics is not smooth.

As of now, China’s degradable plastics are still in the stage of publicity and promotion. The degree to which they can be marketized is not very high though there has been some progress made when it comes down to trying green packaging for certain products. In industries mandated by the state, such as disposable plastic cups, lunch boxes, cutlery, and other daily plastic products in the catering industry, the proportion of using degradable plastics is relatively high. As Zhang Jindong, chairman of Suning Holdings Group, said during the two sessions this year, promoting green packaging in the logistics industry is a systematic project, from the use of green recycling products to the establishment of a packaging recycling system and the reduction of express packaging consumables. It requires not only the “marriage” of the government and enterprises but also people’s deep-rooted green ideas in daily life.

# In addition, the market price of degradable plastic is 2-3 times that of ordinary plastic products.

Degradable plastics have a higher profit level than ordinary ones, but they also come with more risks.The first is higher costs, larger capital occupation, and poor acceptance of downstream companies. The second is that degradable plastics have a certain shelf life. Sales are not smooth, and the risk of loss for the company is greater.

# The degradability of the polymer

The biodegradable polymer is not designed for heavy-duty use and may break down more easily than other materials.

As far as the results of current research and production technologies are concerned, it still takes a long time to make them universally available. The low cost of development, time-degrading, and highly efficient bioplastics is the main direction of future research in this field.

it’s encouraging to see that changes are taking place, and relevant companies have been working hard in the fields of research & development,especially in the application of packaging materials, plastic films, medical materials, and other fields. A revolution with many bright spots around green packaging is ongoing

Conclusion:

To sum up, in the long run, increasing domestic environmental awareness will broaden the use of degradable plastics; increasing demand for environmentally friendly materials abroad will increase exports of degradable plastics, and the maturity of degradable plastics production processes will drive costs.

Gradually reduced to the acceptable range for downstream. With the maturity of various conditions, due to its unique properties, the development prospects of biodegradable polymer materials are extremely broad. At the same time, it also plays a huge role in reducing environmental pollution and creating a pollution-free environment for human beings. In the future, the development and research of biodegradable polymer materials should mainly focus on the competing polymer varieties in terms of the basic properties, molding and processing properties, and the price of polymers.

About PrimePac

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in the UK to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

Network

With our team in China and UK working as one, we reduce inefficiency so that you deal with one streamlined team from manufacturing right to delivery.

Service support team located in Guangzhou, the manufacturing hub of China, providing rapid response, and local industry knowledge. Warehouse and 3PL network located in Sydney, to provide rapid distribution, and delivery to your customers.