Meaningful truth about Food Packaging You Need to Know

Introduction

In today’s thriving food packaging market, it’s more important than ever to find quality solutions.

Food packaging lies at the very heart of the modern food industry and very few foods are sold unpackaged.

Good packaging prevents waste and ensures that the food retains its desired quality throughout its shelf life

With the growing demand for food products, it’s essential to find reliable packaging that will protect your goods.

In this article, we’ll cover the following topics so you can make an informed decision about your next packaging purchase:

- the packaging market

- the importance of food packaging

- food packaging requirements in the UK

- food packaging innovations and solutions in the trend

- and more

Take your time and check them all out below.

The food packaging market

As data reveals, every year there are billions of dollars spent on packaging food and other items.

In fact,60% of all packaging stuff contributes to food products.

Earlier in the 20th century, most foods come without much packaging. People weighed and measured them directly and then placed them in bags. Or collect them with the shoppers’ bag and carry them home.

At that time, packaging was still a strange term for most people.

But today, packaging has become a massive and lucrative industry, given the increasing demand for food packaging products.

And often, it is the look of the packaging that persuades the customers to buy the food inside. Guess you might have a similar experience as well.

As a result, the food packaging industry is thriving currently.

Find more about the packaging market.

In today’s society, food packaging has become more than just a way to protect food from contaminants. It is also an important tool for preserving the freshness and nutritional value of food. In fact, advances in food processing and food packaging have played a major role in keeping the U.S. food supply among the safest in the world.

However, packaging technology must strike a balance between these various concerns, including energy and material costs, increased social and environmental awareness, and strict regulations on the disposal of pollutants and municipal solid waste.

Why food packaging is important?

Because food packaging can help you with so many things you might not even realize before. A nice food packaging solution can:

Protect your food

Quality food packaging can protect your food from damage or contamination. On the other hand, food without proper packaging can be bad for many factors, typically micro-organisms, air, moisture, and toxins. Food packaging can delay product spoilage, retain the beneficial effects of processing, extend shelf life, and maintain or improve food quality and safety. In this case, packaging protects against three main external influences: chemical, biological, and physical.

Many products, especially food require more extra care than the other goods in many cases. They need protection against falling, crushing, and pushing during transport, the fruits for example.

In this case, a rigid package like a laminated container would definitely be a great helper. The container will make your fruits stay close together and protect them. As the saying goes, unity makes strength, this gives them enhanced strength against the force.

In the meantime, you need good food packaging solutions with nice performance against the climate. Factors like temperatures, light, and humidity can all affect the shelf life of the food.

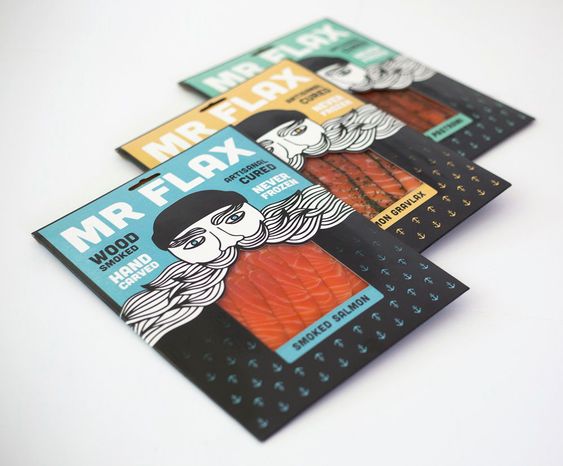

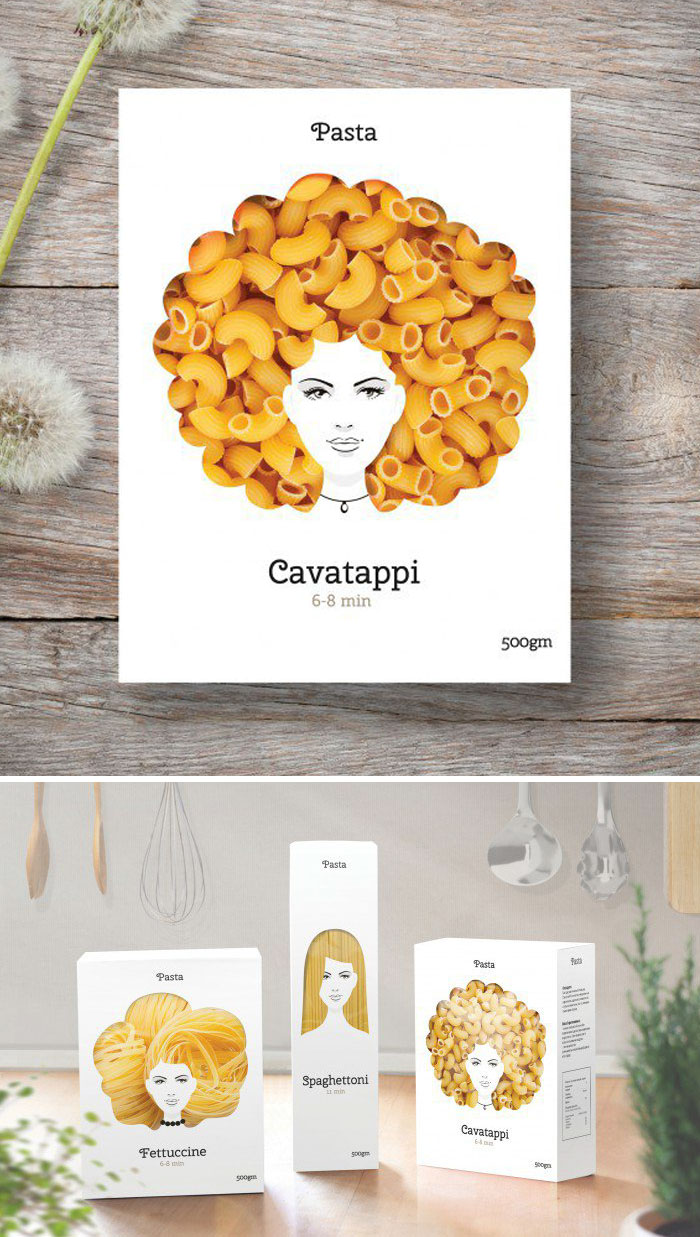

Make your food stand out

As we discussed above, there are times you buy the food because of its beautiful looking.

So, excellent packaging with creative designs can really make your food products stand out and boost your sales.

At the same time, food packaging as a media itself can contain lots of information. That is to say, advertising on the packaging is another way to have customers identify your products among the many.

We believe you can recognize to forget the famous coke brands on the shelf. And the way their companies do the packaging just contributes a big part to that. The shapes, the logo, the color, and all other elements comprise the whole thing. Food packaging serves as part of the quality of your products today.

Ease the transport

When it comes to transport, the convenience to move is also important besides protection during the process.

Thus, a good solution for food packaging is easy to handle, such as moving and lifting.

At the same time, space also matters for transport. Sometimes, you just hope that box can fit into space and complete a full lorry load at a time. For cases like that, you’ll need packaging solutions that could tailor to your need. A well-designed food packaging can contain more products with the same materials and cost.

Innovations in packaging have made it easier than ever to cook an entire meal with little preparation time. For example, cookie makers recently introduced soft bags that feature notched sections for easy access during cooking and sealing-these are perfect if you want quick snacks on hand! The new cap design also allows products like food cans or bottles to be opened without destroying their contents because of how easily resealable these types can get when compared to other models available before now. A sealing film with a peelable seal covers the opening prior to sale and allows resealing after opening. Modern retail formats provide consumers with the convenience of one-stop shopping and the availability of food around the world, but this also means that more packaging waste needs to be disposed of.

A packaging that saves space brings you money, given the increasing price for space today. In other words, you will save the cost of transport with suitable food packaging solutions.

Offer useful information

As you know, you can find plenty of useful information on food packaging.

The ingredients, use-by dates, manufacturing information and etc.

And the barcode as well, which is very important for shops and supermarkets. Today, we’re all used to the check-out process at the cashier. Remember the barcode scanner?

But think of the scenario, if there’s no barcode on it, how much more time are we going to spend? Too hard to imagine right? And the food packaging is the thing to display the barcode. We guess you rarely see a barcode on the food itself, don’t you?

All these factors lead to the growth of the food packaging demand. Along with the increasing needs, there are requirements for food packaging.

The importance of designing excellent packaging for your product can not be overstated. Packaging might seem like a minor detail, but it’s what first catches people’s attention when they see the beauty or uniqueness in front of them on store shelves across America!

The way we package ourselves speaks volumes about who are as an organization–from our name all the way down to how much information is written on each label so customers know exactly why buying this particular preferred brand will make their lives easier.

Now let’s check the case in UK.

Safety and packaging standards in the UK

Who develops the standards for UK food and food packaging?

FIC does. March 24, 2021 – England’s Food Information Regulations 2014 enable local authorities to enforce European food information for consumers.

What are the food packaging requirements?

Food safety is always an issue worth our undivided attention.

It is important to make sure the packaging is safe for food products. If you’re doing a food business, the case matters more for you.

Find more details in the following content.

According to Standard 3.2.2 – Food Safety Practices and General Requirements, a food business must:

- Use packaging materials that fit its intended purpose

- Use material unlikely to cause food contamination

- Make sure food safety during the packaging process and guarantee no contamination during the process

The risks during the packaging process

There are chances the food becomes unsafe due to food packaging mistakes. For instance, the following cases can damage food quality.

- some pollutants get into the food during the packaging process

- hazardous bacteria infected the food from damaged packaging

- the packaging debris or fragments break off and then enter into the food, typically plastic or glass pieces

- poisonous substance from the unsafe packaging dissolves and stains the food

Food packaging is an essential part of any successful food business. It’s important to ensure your products are safe and potent, which means finding the best quality materials for their intended use – like avoiding chemical exposure or bacteria growth when possible!

Reduce the risks by choosing the right packaging solutions

Here are a few tips and principles for your choice:

- always use food-grade and clean packaging

- make sure the food packaging is complete and not damaged

- buy from reliable suppliers like PrimePaclearn the ingredients of your food and double-check the packaging, make sure it is suitable

- ask your packaging suppliers for certifications of their packaging products as the proof of food-safe quality

- pay attention to the instruction and symbols on the packaging, and make sure the food packaging fits your needs

Use packaging in the correct ways:

- think further in advance about where to store the packaged food. And make sure the packaging solution is safe enough for the food

- handle the packaging with care and clean hands

- store the packaging in a clean place and double-check the environment to avoid damage

- always use proper ways to clean and sanitize the packaging. And ensure the methods have no impact on food safety

- always avoid re-using single-use packaging and reuse packaging only if safe for the food

- use enhanced packaging solutions to avoid chemical leaching in the case of any risks

Food packaging labels

To sell food and beverage products, labels must be:

Clear and easy to read

Timeless

Easy to understand

Easy to see

Not misleading

If you sell food in the UK (England, Wales, and Scotland), you must also provide the name and address of the UK or EU business responsible for the food information.

If the business is not located in the UK or EU, you must provide the name and address of the importer.

Why do we need food labels?

Food labels provide us with information so that we have a better reference for buying the food, typically the following items:

- the food description

- ingredients of the food in detail

- information for nutrition

- use-by date or best before date

- instruction like ways to store and prepare

- warnings if the ingredients are likely to cause allergy

Requirements for food labeling

When it comes to the requirements for food labeling, the following information is necessary to display according to the Code by FSA. And that applies to food packages for retail sales and catering purposes.

Name or description of the food product

Well, the name or description of your food must appear on its package labels. And this information should be clear enough so that you can identify it apart from all other foods in similar categories.

The food we buy has to be correctly labeled and advertisers are responsible for the accuracy of their labels. They shouldn’t display fake information or misleading so as you can avoid being tricked into buying something harmful to your health.

Name and business address for suppliers of UK or New Zealand

The food package labels should show the name and the UK or New Zealand business address of the suppliers.

And the term “supplier” refers to the following roles:

- packer

- manufacturer

- vendor (the business that sells the food)

- the importer (the business that brings the food into the UK)

And the requirement of the business address is worth our attention. The address MUST BE a PHYSICAL ADDRESS and NOT a POST OFFICE BOX.

Ingredient listing

The food packaging labels should list all of the following items unless with exemption:

- ingredients (any substance, including all additives added to the food during the whole process from preparation, manufacture to handling the food)

- compound ingredients (any ingredient comprising more than 1 ingredient, like egg noodles. Typically, egg noodles are made of flour, water, and egg.)

And there are requirements for the displaying order of the ingredients and compound ingredients. Manufacturers must display them in descending order.

At the same time, the names of the ingredients should be detailed enough to describe them. And make sure they are correct as no misleading or deceptive information is acceptable.

The date marks

Pretty easy to understand, the food package should have a dark mark on either item below:

- The best before date is a reminder that the food might remain safe to eat after this point. However, you should always take care of your groceries and use them quickly or else they’ll start going bad which costs us money in lost produce value.

- use-by date. This date refers to the safety deadline for the food. That’s to say, if you eat the food after that date, it is risky for your health. And any food is not allowed to sell after the use-by date.

The date marks rules apply to all packaged foods with a shelf life of 2 years or less.

Lot identification

Lot identification can identify:

- the production batch of this food

- the place of packaging or production of food.

If there is a food safety problem, then this information will play an important role in the recall of products.

However, marking the date and supplier’s detailed address information usually meets this requirement.

Besides, some foods do not need to be labeled with batches, including:

- ice cream/rock candy separate section

- small package food. Batch identification is included when bulk packages or containers for sale are stored or displayed.

Directions for use or storage

If you don’t know the potential threat of certain foods to your health and safety. Then the food label of these products must include instructions for use and storage.

Follow these instructions to ensure food safety before use within the shelf life. For example, “refrigerate after opening” or “store away from sunlight.”

Nutrition information panel

The nutrition information sheet will give you a detailed introduction to the nutrient content of the food. It includes:

- protein

- energy (kilojoules or calories)

- saturated fat

- carbohydrate

- sodium (salt)

- sugars

- fat

There is a standard format for this nutritional information, which shows the average nutrient content per serving and per 100 g (or 100 ml, if liquid) of food. If you want to know more about standard 1.2.8 and nutritional information requirements, you can refer to FSA.

Percentage labeling

If the key ingredients are already mentioned in the food description. Then, the label of some packaged food must show the percentage of “characteristic” ingredients in the food.

For example, if there is a yogurt called strawberry yogurt, the producer must list the percentage of strawberries in the yogurt ingredient list.

Country of origin

Food packaging labels must indicate the country where the food is manufactured or produced, or specify that the product is made from local or imported raw materials.

If the ground meat coIf you sell meat, fish, or seafood products to end consumers and mass caterers then the country of origin label must be included on your packaging.

You can also use an alternative label in some cases instead if full compliance with this regulation from a batch from more than one country/region, please label the product with:

If the country/region does not include the UK, then “Country of origin: Non-UK”

If the country/region includes the UK, then “UK and Non-UK”

For ground meat sold in the UK, you can continue to refer to “EU” and “non-EU” until September 30, 2022.

From October 1, 2022, you must use “non-UK” or “UK and non-UK” when the label does not list each country of origin.

Legibility requirements

To facilitate consumers to easily understand the label information on food packaging. The label must be simple, clear, and comprehensive, and it must be in English. It is also important that the font size of the food warning statement must be greater than 3 mm high, and for small packages, it must not be less than 1.5 mm.

If you want to know more, the FSA user’s Guide on legibility requirements for food labels contains more letters that you can check out.

Other labeling requirements

nutrition claims (Standard 1.2.8)

- health claims (Standard 1.1.3, clause 1)

- irradiated food (exposed to radiation) or food containing ingredients that have been irradiated (Standard 1.5.3)

- vitamin and mineral content (Standard 1.3.2)

- certain milk products and royal jelly (Standard 1.2.3, clauses 3)

- genetically modified food (Standard 1.5.2)

- infant formula labeling (Standard 2.9.1)

- novel foods (Standard 1.5.1).

Exemptions from labeling requirements

Here are some of the less commonly used food labels:

- Food without packaging

- Inner packaging food. They are designed for sale only and generally have no outer packaging. But if there are separate parts of certain substances, people have to make oral or written statements

- Food is produced, packaged, and sold on-site at a sales location.

- Food packaged in the presence of customers

- For whole or chopped fresh fruits and vegetables (except germinated seeds or similar products), customers can see the status and quality of fruits or vegetables through packaging.

- According to the requirements of customers, provide packaged ready-to-eat food.

- Food sold in fundraising.

Even if you produce food that doesn’t need to be labeled. The code also requires you to tell customers some information about food, either orally or in writing, at the time of sale.

Warning and advisory statements

Advisory statements

For certain foods or ingredients that may pose health risks to certain consumers, suppliers must provide advisory statements.

This kind of food or ingredients are:

- If the food contains strong sweeteners, the supplier must indicate that the food contains phenylalanine. Because phenylalanine may affect the health of patients with phenylketonuria who have a rare genetic disease.

- Guarana or guarana extract. For foods containing guarana or guarana extract (a natural source of caffeine), the supplier must indicate that the food contains caffeine.

- As long as the food contains added phytosterols (which may reduce cholesterol absorption), the supplier must state the following on the label:

– when eating this product, people should match it with healthy eating habits,

– this product may not be suitable for children under five years of age and pregnant or lactating women, and

– Phytosterols do not provide additional benefits when ingested more than 3 grams per day.

- For cola drinks containing caffeine, the supplier must indicate on the label that the product contains caffeine.

Warning statements

When food suppliers know that their products pose serious health hazards, they must attach warning statements to these foods. For example, Bee product royal jelly contains an ingredient that can cause severe allergic reactions in some people and even lead them dead if not handled properly by medical professionals who are aware of this issue with behaved Kirkpatrich cream.

Full list of advisory statements

In addition, the code of food standards requires Advisory statements for certain products. Find the full list on https://www.foodstandards.gov.au

More about the labels

Check if you need a poultry optional indication certificate

You must ensure that each shipment is accompanied by a poultry meat optional mark certificate issued by the GB competent authority if you meet any of the following conditions.

Export of poultry meat from the UK to the EU with one or more optional signs (frozen or farmed method signs).

Shipments of poultry with one or more optional indications from the UK to Northern Ireland.

From 1 July 2022, you will need an optional indication certificate from the EU competent authority to import poultry meat with one or more optional indications from the EU to the UK.

Allergic issues caused by the food

Food allergies are common to see in our daily life. If you’re allergic to some food, you might understand the feeling more than anyone else.

And the typical food allergens include wheat, soy, sesame seeds, nuts, eggs, milk, fish, etc.

It might be easier to avoid them if you know them in advance. But there are times allergies occur to you even before you realize it. The reason can be getting the wrong food into the stomach.

So, it’s important to display the potential allergens on the food package label.

Don’t forget that especially when you are running a food business. Some allergies can even kill.

So, always be careful when listing the ingredient information on the food package.

Ingredient lists and percentage labeling

Ingredient lists

The supplier must list the ingredients in descending order of weight.

This means that when suppliers produce products, the first component contributes the most and the last one contributes the least. For example, if sugar is at the top of the list, sugar accounts for the largest proportion of the product.

If the product contains added water, the supplier must list it in the batching table according to its feed weight. Also, any water lost during processing (e.g. water lost in the form of steam) should be noted by the supplier. The only exception is added water:

- less than 5% of the finished product,

- being part of the broth, brine, or syrup in the ingredient list, or

- for the reconstruction of dehydrated components.

Sometimes, foods contain compound ingredients. The producer mixes two or more ingredients. This is the compound ingredient. For example, ketchup can spaghetti, which is made of flour, eggs, and water.

And the supplier must state all the ingredients that make up the composite components in the table.

Unless the amount of this compound is less than 5% of the final food. For example, one compound that may be less than 5% of the final meal is tomato sauce (made of tomatoes, peppers, onions, water, and herbs) on a frozen pizza.

However, if the composition of the compound is a known allergen. No matter how much of this ingredient you use, you have to label the food package.

Percentage labeling

The supplier must label most packaged foods with the main ingredients or percentage of ingredients in the food. Then consumers can compare similar products.

The main ingredient of strawberry yogurt is strawberry. The label says, for example, 9% strawberries. Another example of a typical ingredient is the cocoa solids in chocolate. There are also foods, such as white bread or cheese, which may not have characteristic ingredients or characteristic ingredients. It’s all possible.

Nutrition, health, and related claims

On January 18, 2013, a new standard to regulate nutrition and health claims on food labels and advertisements became law. Food companies must comply with the new standard (standard 1.2.7 – nutrition, health, and related statements) until January 18, 2016.

Health claims

Safer Food, Better Business (SFBB)

Food safety management procedures and food hygiene regulations for small businesses.

As a food business, you and your employees need to maintain good personal hygiene.

This fact sheet provides you with information on how to ensure the safety of your employees and the food you serve.

The Safer Food, Better Business (SFBB) package includes information on

Cross-infection

clean up

No Chills

Cooking

Management

Use diary

A practical and easy-to-use package will help you too.

Comply with food hygiene regulations

Demonstrate what you are doing to prepare food safely

Train your staff

Protect your business reputation

Improve your business

Improve your food hygiene score

Self-verify: notifying established food-health relationships for general level health claims

If food companies can self-verify the food-health relationship, it can help enterprises to make general-level health statements.

However, businesses need to self-certify food health relationships before they are declared on food labels or food advertisements.

At the same time, the company should inform FSA of this relationship.

Also, FSA maintains a list of food hygiene relationships. This is the public record of food companies. This suggests that these businesses choose to self-confirm food health relationships to support general-level health claims.

Also, a food business cannot use a relationship on another food business’s notification list. If a food business wishes to file a general health claim based on a listed relationship, it must conduct its own systematic review. And inform FSA of this relationship.

Who checks nutrition content claims and health claims on labels?

For England, DHSC is responsible for nutrition labeling, while the Welsh Government in Wales and the Scottish Food Standards Agency are responsible for Scotland. Local authorities enforce these regulations in England, Wales, and Scotland.

Presentation of nutritional information

Nutritional information should be presented in

In a tabular format with numbers aligned

Where space does not permit, statements may appear in a linear format

Energy values must be expressed in kilojoules (kJ) and kilocalories (kcal), and nutrient amounts must be expressed in grams (g)

All elements must be in close proximity to each other. These elements must be presented together in a clear format and, where appropriate, in the order of presentation as specified in Annex XV of the EU FIC. Nutritional information must be expressed in units of measurement per 100 g/ml using the units of measurement specified in Regulation 1169/2011

Vitamins and minerals must be expressed as a percentage per 100 g/ml and as a Reference Intake (RI)

Pre-Package Nutrition Labeling Consultation

In Northern Ireland, the FSA is leading the “multiple traffic lights” in front of the current UK package nutrition labeling scheme. The scheme is seen as an important tool to support consumers to better understand the nutritional content of their food and drink.

In partnership with the Department of Health and Social Care (DHSC), Food Standards Scotland, and the Welsh Government, the FSA launched a four-nation consultation on package nutrition labeling in July 2020.

The aim of the consultation is to gather views and evidence to help inform any future improvements to ‘multi-traffic light’ labeling and to ensure that UK labeling remains the most effective in informing healthier choices.

Truth in labeling: measures, weights, and legibility

Truth in labeling

UK food law requires food companies to label their packaging. The labels placed on the package by food enterprises shall not mislead consumers through false, misleading, or deceptive statements.

Under the Northern Ireland Protocol, goods sold in NI continue to follow EU rules for food labeling. There are changes to labeling that apply from 1 January 2021

However, the UK government recognizes that businesses will need time to adapt to these new labeling rules.

The UK government is working with the Department of Agriculture, Environment and Rural Affairs (DAERA) and district councils in NI on an enforcement approach of new labeling requirements on the NI market that takes these challenges into account.

In line with previous rule changes for labeling, there’s a proportionate and risk-based enforcement approach particularly for:

- identification marks

- Food Business Operators (FBO) address requirements

- ‘UK(NI)’ origin labeling requirements

Name or description of the food

The supplier must label its exact name or description on the package of the food. This can indicate the true nature of the food.

For example, “strawberry yogurt” should contain strawberries. If it’s strawberry yogurt, not real strawberry. Then the supplier should indicate on the label is strawberry yogurt.

Weights and measures

Weighing and measuring are some of the most important pieces of information about food. Therefore, the supplier must attach accurate weight and size information (quantity of food in the package) to the food.

Legibility requirements

Food standard specification requires that the label must be clear and eye-catching. And it is different from the background and uses English.

Next, the size of the text in the food warning statement must be no less than 3 mm high.

Also, unless on small packages, the type size must be at least 1.5 mm.

Food packaging innovations

The growing global environmental pollution has caused us to rethink how food is packed.

A recent study by the EPA found that nearly 45% of US landfills are dedicated just to discarded packages related to foods we don’t eat anymore, making it one major component among other things such as paper products or plastic bottles.

We should be aware that using sustainable food packaging is no longer just an option for individuals. Instead, it has become an urgent need to protect the global environment.

Many people are trying to reduce the amount of food packaging they bring into their houses.

But soon they will find that it’s not an easy task.

Food packaging is an area where everyone can take action to reduce the amount of waste they produce. Private individuals should try their best not to use too many food packages,

While businesses and political entities also have a responsibility in this matter by taking joint efforts with each other for success!

Innovations in sustainable food packaging are leading us a further step to a sustainable life.

Meanwhile, we still have a long way to go for a fully sustainable goal.

And the good news is, that more and more businesses are adopting new materials. At the same time, government policies also help to accelerate progress.

And PrimePac is one of these businesses with the honor to pay our effort to a society with less waste.

Why do we need innovations in food packaging?

Most of the food we buy now needs plastic wrapping and packaging. It’s useful, right?

But its harm is also obvious–plastic will bring a heavy cost to human beings as well as our environment.

Making plastic requires a large amount of limited and heavily polluting fossil fuels. Research by the Pacific Institute, a global water organization, provides some background.

In one year, the production of plastic for bottled water that Americans bought, consumed a lot of fossil fuels. These fossil fuels are equivalent to about 17 million barrels of oil. As we all know, the heavy use of fossil fuels will make global warming more serious.

So, to deal with the climate crisis, it is important to reduce plastic use, especially the use of single-use plastics.

Moreover, the plastic issue has created some other issues. One of the famous is the pollution of water.

So, environmental organizations believe that recycling plastics is a way to deal with plastic waste. They encourage people to recycle plastics.

By recycling plastics, we can reduce the number of new plastics that will be made.

What’s more, we can move away from a throw-away society towards a circular society, balancing environmental and economic development.

But the fact is that recycling alone is not enough. It can only be a partial and incomplete solution.

Not enough just to recycle plastic food packaging

- One of the reasons is that most plastic food waste in our homes is not recyclable, such as some black plastic items. These plastics cannot be recognized by grading machines at recycling centers. So, it’s necessary to think of other ways to deal with these non-recyclable plastics.

- The second reason that recycling plastic is so expensive, laborious, and energy-intensive? It uses nearly double the number of resources as simply throwing away old bottles. Plus all this work has an environmental cost – like trucks driving around with full tanks producing carbon emissions on our roads.

- One more reason, we can only recycle most plastics once or twice before they are down-cycled. Down-cycled means to be recreated into some lower-value items. Recycling companies turn plastic into fabrics because plastics will not be recyclable after several uses. Obviously, fabrics have a higher value. It is more profitable to turn plastic into fabrics. But it is worth our notice that some clothes made from plastic bottles can no longer be recyclable.

And when plastics enter landfills, they will break apart over time. But the process will usually continue for centuries.

So, next time when you think that buying recyclable plastic items is environmental-friendly, please remember that recycling plastics is usually a one-or-two-time process.

The bio-plastics thing

Many innovations in sustainable food packaging use the idea of bioplastics.

Bio-plastic, also called biodegradable plastic, is a kind of plastic that will break down over time. It is unlike traditional plastic polymers.

Such plastics can be broken down by some living organisms, such as bacteria. And researchers believe that bioplastics can be an effective solution to most of the problems of plastic waste.

As we mentioned just now, most plastics will not break down naturally in the environment or will take several centuries to break down.

So, the existence of traditional plastics will create a waste crisis that will last for generations. Compared with traditional plastics, bio-plastics take a very short time to break down.

Renewable Natural Bio-plastics or Synthetic Bio-plastics?

There are two types of biodegradable plastic.

One type is bio-plastics and the other type is biodegradable synthetic polymers.

Bio-plastics are made from renewable raw materials. On the other hand, biodegradable synthetic polymers are made from petrochemicals. They contain biodegradable additives to make the break-down process faster.

You might feel confused about the terms “biodegradable” and “compostable”.

Biodegradable material can break down into some fragments, while compostable material can break down into useful compost. So, biodegradable plastic may remain inorganic compounds during the break-down process.

But a fully compostable plastics, on the other hand, will break down without leaving any inorganic compounds in the environment.

We have talked about the features of different types of bio-plastic. And the features determine whether the type of bio-plastic is the most eco-friendly and sustainable choice.

The Best Bio-Plastics:

Are fully compostable

Imagine a world where all of your plastics were bio-degradable and even compostable. You could throw them in with regular trash without worrying about harming the environment because they would break down into carbon dioxide, water vapor (or other substances!) meaning these new “bio” derived materials are simply part two – alongside organic foods–of an eco-friendly lifestyle.

Unfortunately, the synthetic polymers are imperfect yet. They will leave behind harmful inorganic compounds that can’t be broken down by bacteria as true bio-plastics do! But we’re on a mission to improve these plastics so they don’t include any more unwanted solid waste for you or me – just one less type of puzzle piece thrown out with your day’s trash at home.

Usefully sustainable, eco-friendly, natural raw materials

The environmental benefits of using bio-plastic are vast, with a truly green material able to be created from resources that would otherwise go into producing food. This can help reduce energy and water consumption within agriculture while also reducing carbon emissions if it’s compostable.

Manufacturers would like to use non-renewable fossil fuels to produce synthetic plastics. It harms the natural environment a lot and also contributes to global warming.

Bio-plastics that are made of renewable resources can be carbon neutral and will degrade completely, but the production process still impacts how environmentally friendly they really are. Some biodegradable plastics have been shown to release harmful compounds into our environment so it’s important for you to consider all factors before making your decision on what type is best.

Bio-plastics have many advantages, but there’s always a downside. For example; the best bioplastics will release methane when they’re burned in landfills– so if you want to be eco-friendly and green with your environmental footprint consider not using them or processing natural materials by small household compost systems instead!

Compostable series are available on PrimePac now. Contact us and get a quote.

Food packaging solutions in the trend

To protect the environment, a good way to reduce the carbon footprint is to choose environmentally friendly packaged takeout food and drinks.

Let’s take a look at the following raw materials that can be used to make fully compostable polymers, which will help to better understand the innovation of bioplastics:

Food packaging with eco-friendly plastic

Potato starch, corn starch, and other first-generation bioplastics feedstocks

Several plant materials can provide cellulosic materials for bioplastics used in the packaging of the global food system.

Also, a series of potato starch, corn starch, and other plants have been used to replace synthetic plastics in food packaging.

However, the materials face criticism because packaging food with food-grade products means taking food from people and animals. With increasing competition for land, it has been criticized that the use of this material may be immoral in the face of global food shortages.

So, the long-term use of land to produce packaging rather than food might remain unsustainable.

Bamboo bioplastics for food packaging

According to the research conducted by INBAR, if people produce well, we can carry out a 100% bio base and complete biodegradation of bamboo plastic substitutes.

What’s more, bamboo-based materials can play an important role in the global bioplastics industry. People can produce about 2 million tons of bamboo-based materials every year.

One example of the second generation of bioplastics is bamboo bioplastics. Growers produce second-generation materials from non-food crops (cellulosic materials).

There are other examples, such as wood, awn, switchgrass, etc. The second generation of raw materials also includes wastes from the first generation of raw materials, such as waste vegetable oil.

Land use is the key to the sustainability of second-generation raw materials. We can’t use land suitable for food production to grow these bioplastic materials, which will affect food production.

So, we have to choose a land that is suitable for food production. And they should be materials that we can grow sustainably, with as little land, water, and other resources as possible.

Algae/seaweed feedstocks for bioplastic food packaging

Another innovation in bioplastic food packaging is the use of algae/seaweed. We call algae the third-generation raw material of bioplastics.

They have a higher yield and higher efficiency than the above materials. And they don’t need fertilizers, pesticides, herbicides, or land. Besides, like the materials mentioned above, they are naturally biodegradable.

However, it is difficult to use algae as raw materials for bioplastic food packaging on a large scale.

First of all, using seaweed or unicellular algae to make bioplastics is more expensive than other bioplastics.

Second, they are not widely used, and researchers need more information to study their applications.

However, in the future, algae-based bioplastics may revolutionize the bioplastics industry. They may play an important role in the development of food packaging.

Mushroom feedstock for bioplastic food packaging

The potential bioplastics base material we can use is not just plant materials.

Interestingly, we can use mushrooms and fungi to make bioplastics. At present, mushrooms and fungi have become another way to study biopolymers.

Besides, people have now replaced polystyrene with mushroom-based materials. Fungi may also have some other applications in the future.

Of course, bioplastics are not the only alternative to food packaging.

Now more and more people are doing research on food packaging with sustainable materials. Businesses and manufacturers are becoming more and more creative when packaging food with other sustainable materials.

For example, leaves, such as banana leaves, can be simply used to wrap vegetables, etc. Our innovation in food packaging materials may also revolve around reducing the total amount of packaging required.

Other eco-friendly food packaging options

Kraft paper

People can recycle 100% of the natural brown kraft paper containers. Because they are compostable and biodegradable.

Also, people use kraft paper to make food packaging has two flip and tray styles. They are simple and fashionable.

Therefore, when the store is using kraft paper food packaging box. Customers and passers-by will immediately know that you are an environmentally friendly organization.

Palm leaf plates and bowls

Palm leaf packaging is very suitable for mobile food trucks or mobile food stalls. There, customers are most likely to consume food or drinks near the food supply area.

Palm leaf plates and bowls are fashionable to take out packaging options. It’s suitable for festivals, fairs, markets and any kind of activity because the food there is on-site. Palm leaf packaging is made from 100% renewable and compostable leaves and water.

Thus, the palm leaf package does not contain any harmful toxins and will degrade naturally within two months after use.

Eco-sugarcane

Ecological bagasse sugarcane containers are 100% biodegradable and compostable. Most importantly, it’s affordable, not as expensive as bioplastics made from seaweed.

What’s more, it has a variety of styles. This includes a clamshell, a tray with a pot cover, and a soup bowl. Sugarcane packaging is made of bagasse, which is the pulp of sugarcane after juice extraction.

They are non-toxic and durable. They are very environmentally friendly materials.

You can evaluate each green takeaway packaging option to determine which style is best for your business. Just to remind you, you don’t have to choose only one style of packaging. In other words, you can mix and match different styles of packaging according to your needs.

There is no doubt that your customers will support you in reducing waste and protecting the environment.

More about eco-friendly packaging on Why Use Eco-friendly Packaging for Your Online Business.

Sustainable packaging

Besides eco-friendly packaging solutions, sustainable packaging is another talking point in the packaging industry in the UK.

Sustainable packaging is the development and use of packaging which results in improved sustainability.

(source: https://en.wikipedia.org/wiki/Sustainable_packaging)

In other words, it means packaging with zero/less impact on the environment. Typically, recyclable, compostable, and reusable packaging. And it is a further step of eco-friendly packaging.

Find more about sustainable packaging in the Sustainable packaging industry in 2020.

What can we do as citizens around the globe?

To reduce the amount of food packaging we take home, we can make some changes. For example, we can:

- Grow at least some of our food to prevent food shortages due to the use of food packaging.

- Buy local, fresh, organic produce whenever possible. Instead of buying processed, pre-packaged foods, cook your own fresh ingredients.

- When shopping, we bring our own shopping bags instead of using plastic bags in the store. Similarly, when we buy takeout food, we also bring our own containers to hold the food.

- It’s a good idea to make an initial list of what you want before going shopping so that when it is time for buying things, your funds are committed.

- Replace retail purchases with wholesale goods, or shop in zero-waste stores as much as possible.

Conclusion

A quick review of the contents above. We’ve discussed the following things in this article:

The packaging is important because nice packaging solutions can protect your food, make your food stand out, ease transport, and offer useful information.

The requirements for food packaging in the UK, including safety and packaging standards, and the detailed requirements for food packaging labels.

Food packaging innovations are greatly in need. And recycling is not enough to solve the problem while bio-plastic is more friendly to the environment.

We also talked about trendy food packaging solutions today. That includes the eco-friendly plastic family members: plant starches, bamboo bioplastics, algae/seaweed feedstocks, and mushroom feedstock. And other eco-friendly food packaging options such as kraft paper, palm leaf plates, bowls, and eco-sugarcane.

Besides, we also talked about one of the major talking points in the industry: sustainable packaging.

And what we can do as citizens around the globe.

Like this article? Share to as many as your friends and enjoy it together. We appreciate it if you could bring them to our website and follow our blogs.

The Helpful Guide to Choosing Your Beverage Packaging

Introduction

The packaging of beverage products is more than just a pretty box. It’s an integral part of launching new items, acting as the interface between you (the producer) with consumers who will buy what they see or touch firsthand!

Quality beverage packaging solutions are in great demand nowadays, given the growing need for beverages.

This ultimate guide is going to help you if you are:

- a packaged beverage supplier

- involved with the beverage supply chain

- a supplier of the beverage packaging industry

- any other needs for beverage packaging solutions

The beverage packaging market

Studies revealed that the global beverage packaging market size expects to reach $133.3 billion in 2026.

A lucrative number, given the growing demand for a variety of beverages.

And as the final part of the beverage supply chain, the beverage packaging industry benefits from the ever-growing beverage industry.

When it comes to beverage packaging, it is a complex process due to the various beverage types and requirements. The reason is, different types of beverages require different materials and containers, for convenience or need to keep fresh. And beautiful designs to catch consumers’ eyes as well.

Factors boosting the beverage packaging market growth

Improved lifestyles and increased per capita income (mainly in developing economies) have promoted the consumption of packaged beverages. Thus, the demand for better and convenient packaging technology is promoted.

Convenience factors in the beverage packaging industry allow for reduced waste and increased packaging resealing capabilities in the distribution process. It also allows for increased portability and reduced weight. So, it helps to save costs and thus boost the beverage packaging market.

Moreover, in urban areas, the increase in per capita income and the decline in water quality have led to an increase in the global consumption of bottled or packaged water. At present, the bottled water market is one of the fastest-growing markets.

Therefore, the rapid growth of the bottled water market has also promoted the growth of packaging required for bottled water production.

Also, many manufacturers have updated their production technology and applied automation technology in the production process. Therefore, production efficiency has greatly improved.

At the same time, the quality of products has also improved. These factors together lead to the overall growth of the beverage packaging market.

On the other hand, growing concerns about obesity and high sugar intake are leading to packaging strategies.

For example, sodas, alcohol, and sugary drinks. In the future, ordinary packaging may hinder the market.

However, the application of bioplastics in beverage packaging will create favorable opportunities for the growth of the beverage packaging market.

Also, there are alternatives to bioplastics known as biopolymers. It is a polymer made from plant-based materials rather than petroleum-based materials. So, this enables bio-PET containers to degrade and reduce plastic contamination.

The non-alcoholic beverage market accounts for more than half of the global market share.

However, the demand for packaging solutions will also grow rapidly by 2026.

Competition Analysis

The main market participants described in the report include Amcor plc, Ball Corporation, Orora Limited, Reynolds Group Holdings Limited, Smurfit Kappa Group plc, SIG Combibloc Group AG, Crown Holdings, Inc., Mondi plc, Stora Enso Oyj, and Tetra Laval International S.A.

Many competitors in the beverage packaging market have taken product release as their main development strategy. They hope to expand their product portfolio of recyclable beverage packaging. For example, in July 2019, SIG launched the signature pack 100 in France. This signature pack 100 is a sterile carton. And it’s aluminum-free, made from plant-based and 100% biodegradable polymers.

Similarly, in August 2019, Amcor developed a new line of polyethylene terephthalate (PET) bottles for the Salzburg beer brand in Brazil. The new bottles can last for four months, and people can recycle 100% of them using existing recycling technologies. Besides, the bottle has a glass-like appearance and has a metal crown, which is very beautiful. This makes it more attractive to customers.

Why beverage packaging solutions worth our attention?

Beverage packages with proper designs can extend the shelf life of the beverage. That is to say, if you have the right options for your beverage packages, your beverages will live longer!

At the same time, a proper package solution can also save your material cost. And generate less waste to the mother earth.

Also, the packaging materials used for drinks include glass, polymer, metal, cardboard, and their combinations. The shelf life, chemical composition, and value of beverage determine what material the producer uses for packaging.

Types of beverage packaging

You need to decide which containers your beverages will be placed in.

You can choose from a variety of options, but keep these factors into account when balancing cost and availability as well as compatibility with formulation requirements for each individual beverage product line that you’re looking at targeting!

By beverage packaging materials

Glass beverage packaging

The advantages of glass beverage packaging are numerous. First, it’s non-toxic and tasteless – you can drink it with confidence! Furthermore, the safety is unparalleled.

Second, it is transparent. Then the glass beverage packaging will be very beautiful so that customers can see the appearance of the beverage. You know, it can stimulate their desire to buy.

The sealing of glass beverage packaging is very good in this way, to avoid the microorganism and chemical reactions that cause deterioration.

The common material for beverage packaging is glass. It’s affordable and easy to find, which makes it one of the more popular choices among packagers who want something that can be used without too much hassle or expense upfront cost-wise.

Glass is a great material to use for storing your drinks because it can withstand high temperatures, pressure, and cleaning agents. You’ll never need to worry about bacteria growing in the container with this type of glass!

Glass beverage packaging not only looks great, but it’s also environmentally friendly! Glass bottle recycling can save energy and reduce the waste capacity of landfills.

Thus, glass beverage packaging is the preferred packaging material for beer, fruit tea, jujube juice, and many other beverages.

The glass beverage packaging has some disadvantages. For example, it can make drinks heavy and difficult to transport due to the particularity of this material which makes it more expensive than other types for transportation purposes too.

Metal beverage packaging

Metal beverage packaging offers a great solution for businesses who want to keep their drinks cool and safe. It has the ability to block oxygen, water vapor as well steam while also being able to withstand high temperatures without breaking down or dissipating any flavor in your product!

At the same time, it can also block light, especially ultraviolet light. Therefore, it will not cause deterioration or a change of flavor.

The metal packaging of this product has made it easy to transport and store, which is why the company was able to increase its sales radius.

Then, the metal beverage container is not easy to get damaged and easy to carry.

Nowadays, many young people like metal beverage packaging, cans for food & beverage packaging with easy-open lids. However, it adapts to the fast-paced life of modern equipment and is widely used in tourism life.

One of the reasons why metal beverage packaging is so popular is that it is friendly to the environment.

These packages are made from a material that not only saves resources and energy but also eliminates environmental pollution. The metal can be scattered in your garden after corrosion without hurting anything.

Compared with glass beverage packaging, metal beverage packaging has more styles and a more beautiful appearance.

Metal containers are a great way to express your style and creativity. The beautiful metal luster, coupled with colorful graphic printing will make the gift you’re giving stand out from any other.

But its disadvantages are also obvious. First of all, its chemical stability is very poor.

Under the condition of acid, alkali, salt, and humid air, it is easy to rust. So, to a certain extent, it limits the scope of its use. Secondly, its price is relatively expensive and its economy is poor. However, this shortcoming is also gradually improved through technological progress.

Plastic beverage packaging

Plastic is a synthetic or natural polymer resin as the main material. After a special process, it can be used to package food and drinks.

The original container for beverage packaging was glass bottles, followed by paper composite cans. Later it became a PET bottle. Now rigid PET bottles are the biggest packaging materials for carbonated drinks and non-carbonated beverages.

Lightweight and convenient for people to carry, plastic beverage packaging is not afraid of breaking or damaging easily when transported over long distances.

It’s a great choice in situations where you need your drink fast but doesn’t have access to glass bottles like on beach trips!

With its strong acid and alkali resistance, this material is perfect for producing plastic beverage packaging. It also makes the process of manufacturing very easy to control.

However, when using plastic beverage packaging, you should pay special attention not to let it come into contact with vinegar or detergent.

At the same time avoid direct sunlight, high temperature, etc. To avoid chemical reactions between plastic beverage packaging and these things.

Besides, when you buy plastic tableware, you should choose the product with PE (polyethylene) or PP (polypropylene) label. And choose less decorative patterns, colorless, tasteless, smooth surfaces of plastic products.

Even though plastic beverage packaging is recyclable, it is disposable. Compared with glass beverage packaging which can be reused, plastic beverage packaging is a less environmentally friendly packaging option.

Paper beverage packaging

Paper beverage packaging is of low cost and lightweight. This makes it easy to carry, which is conducive to the transportation of logistics. In addition, the beverage packed with paper materials does not need to worry about metal dissolution and odor.

However, paper beverage packaging generally uses high-strength raw cardboard materials. This is because pure paper packaging materials are difficult to package drinks. Commonly referred to as paper beverage packaging. Almost all of them are paper-compatible materials.

Also, composite paper packaging is widely used in beverages, especially non-carbonated beverages. Among them, dairy products are the largest application field. Fruit juice, tea, and coffee are the most commonly used compound paper packaging in beverages.

The biggest advantage of paper beverage packaging is that it can be recycled and reused. This is very good for environmental protection.

However, the pressure resistance and sealing barrier of paper-plastic composite beverage packaging are not as good as glass beverage packaging, metal beverage packaging, and plastic beverage packaging. And it can’t be heated at high temperatures.

Therefore, paper beverage packaging in the preservation process will encounter many problems. For example, it will reduce the heat-sealing performance of PE film due to oxidation.

Or it will be because of creases, under the fiber hardening and other reasons become uneven, resulting in the appearance is not beautiful. It will even cause the filling molding machine difficult to feed the problem.

By packaging types

Beverage bottle packaging

The beverage bottle packaging is generally divided into glass bottles, plastic bottles, metal cans, and other types. Here we will introduce you to glass bottles, plastic bottles, and metal cans.

Glass bottles have obvious advantages, such as being environmentally conscious and not disposable packaging. The transparent shape makes them very beautiful; however, their disadvantages also stand out – glass is heavy so it’s difficult to carry around with you all day long or if someone bumps into us accidentally then there could be scratches on our clothes from broken pieces of jars!

Moreover, it is not convenient to clean if it is reused. If it is not cleaned, it is easy to cause cross-infection of bacteria and viruses. The material of a glass bottle is very special, and its price is high.

Now there are a lot of bad businesses, to reduce costs, will make fake glass bottles to replace the real glass bottles. And fake glass bottles are likely to have adverse effects on people’s health.

Compared with glass bottles, the cost of plastic bottles is very low. And it’s light and easy to carry. But the barrier of a plastic bottle is so-so, and it is easy to react with other chemicals from the packaged beverage. That can cause the beverage to deteriorate.

However, with the continuous update of new materials and technologies, plastic bottles with new materials have emerged. This can overcome the shortcomings of plastic bottles to a certain extent.

Beverage packaging boxes

The biggest advantage of beverage box packaging is that it is hygienic and convenient to drink. It generally adopts an aseptic and healthy packing box.

People use straws when drinking. This is to prevent consumers from bringing dust and bacteria into the beverage box when using the straws. Therefore, people can safely drink.

Besides, the beverage box packaging is very beautiful, its shape is regular, with a strong sense of design.

Moreover, it can avoid light and is convenient for the long-term storage of drinks. At the same time, it can be well isolated from the air and prolong the shelf life of the beverage.

Tetra Pak is a liquid packaging product developed by the Tetra company of Sweden. It’s one of Europe’s largest suppliers of milk, juice, and beverages among other products- which makes it perfect to be used as carton boxes.

Beverage pouch packaging

Beverage pouch packaging refers to the packaging pouches for beverages using processed phenylene materials.

Typically, beverage pouch packaging is common to see in packages for milk, juice, and other drinks.

Beverage pouch packaging has the characteristics of acid resistance, corrosion resistance, and aging resistance. This means that the beverage pouch packaging can play the role of isolation and protection. And the cost of beverage pouch packaging is very low, low price is a good choice for manufacturers to save production costs.

Also, the production of beverage pouch packaging is simple and easy to use.

You can put your favorite beverages in a sustainable, eco-friendly package with ease. The process is easy and straightforward – all you need to do it seal up the bag for good measure.

How to choose the right beverage packaging?

You are an ambitious entrepreneur who has created something that will change the way people drink liquids. But unless you plan to sell it only by the glass in your bar and soda fountain. Otherwise, you need some beverage packaging as beverage packaging will affect people’s consumption of liquid drinks.

Now your mind may just jump into a bottle or a bag, right? It’s a good start, but you have a lot to think about.

To decide your beverage packaging solutions: the question to ask

What is your beverage?

The packaging of your drink is more than just a pretty face. At the same time, it’s also this physical container that holds all sorts of things – like carbonation and pressure needs for instance. What are you putting in there? Is it going to mix with other liquids or not enough room left over on top where the product would be visible at the retail level?

All these problems will affect the logistics demand for packaging.

Who is your customer?

The best way to grow your customer base is not by pushing more people into buying something, it’s about figuring out who you are and what type of drinker they might be. Are they experienced, connoisseurs or amateurs? Young professional on a budget crunch but still want good quality alcohol for socializing with friends afterward?

Also, don’t forget that there are legal restrictions on who you can sell certain types of drinks too.

How are your customers going to buy your products?

It’s not just about who will buy it, but where they can find your product. You need to figure out what channels of distribution work best for both retailers and consumers alike.

Once you dig into these questions (don’t worry, you may have multiple answers to the same question). Now, you can start designing your beverage packaging.

Need to Know

The first thing you’ll want to do is find your color value (CMYK or Pantone match). This will help determine what colors are printed on top of each other when creating the final stamp graphic for bottles, boxes, etc. Again, you must use the font you have created. Of course, if possible, you must have the original file of your logo.

Next, you start creating everything specific to each wrapper layer. This will likely include written copies, as well as logos or brand logos. If there are photos that match your taste, you may want to print them on the outer packaging.

Also, don’t forget that you need to make space for the legal signs. Such as bar codes, nutritional information, and alcohol content.

In addition, many things like batch numbers and expiration dates change periodically. You set aside space to label or stamp every batch of drinks you produce.

Although your enthusiasm for drinks is free, the packaging is not. So, you need to consider the cost of printing and manufacturing.

As mentioned above, not every package of your drink is unique. Your product packaging design will have fixed costs (e.g. hiring designers), as well as project costs (labor, materials, such as stamps, and stickers mentioned earlier). It’s like any good drinker, and you certainly want to cut costs.

But sometimes your frugality is not worth it. Better materials contribute to a better presentation. For example, luxury drinks can stand out on shelves with some luxury packaging.

Make your own beverage packaging designs

The first step

The first is to determine what kind of packaging you want: pop cans? Bottle? Or some kind of space-age pouch? Also, are the bottles in boxes or sold separately?

The bottle’s unique shape will make your eyes shine. But with this kind of packaging, how to stick the label can be tricky- because you need a flat or regular surface for printing/pasting.

The cost of unique packaging elements like two-liter soda bottles can be expensive, but they’re an investment. Not only do these containers help keep your product recognizable and appeal to consumers’ nostalgia or preference for olden times.

Your drinks need special lids because they’re different from everyone else’s. For example, the ones with capacities that differ by number or type will be defined better if you have their own lid to distinguish them from others with phobia (fear of uncertainty). You can also choose colors wisely – think about what characterizes your brand identity!

Even if your drink is a regular shape, a beer can, for example. But it still affects your label. Some images look good when they are flat on a computer screen, but when printed on a convex surface, they deform and become ugly.

It’s Dangerous to Go Alone!

When you’re busy making your magic drink, you probably can’t make much time for graphic design at the same time. don’t worry!

Many amazing beverage packaging designers are working with PrimePac, ready to work with entrepreneurs like you.

But don’t just focus on your designers. You should also contact a professional printer at the same time- even if they are different people. Try getting involved early with their needs, because those will have an impact not only on yourself but especially so when it comes down to what type of file format or color options you’ll need later in the production process.

What’s Most Important to You?

You know your drink is delicious, healthy (maybe), and smooth. But what will make it stand out on the wine shelves at supermarkets?

At this point, you need to work with your designers on the so-called “information architecture.”. Arrange your main gains in terms of importance. So this is how to guide your packaging design. Therefore, your design center is the most important, whether it is a brand name, or logo, or other complete.

A Second Opinion

When you and your designers have been working on a design for some time, it’s common that the process will lead to less inspiration or creativity. But don’t worry! This is just one part of what happens in every creative project.

It’s important to get feedback from people who can give you an honest and relevant opinion. You should do as little publicity, set up events or meetings with potential buyers of your product so that they may try it out themselves before making a purchase decision!

There are no problems that don’t need to be understood. You can ask them: what kind of drink is this? Who would like to drink it? Does the packaging reflect the beverage itself? Does it stand out from the competition?

If their answers match your own, Congratulations! It’s time for you to print (follow the delivery instructions discussed earlier).

If there are differences, you need to ask follow-up questions. Then find out how your statement differs from their acceptance. Remember to take these notes seriously and discuss them with your designers. Because it will affect the sale of your drink. And it’s not a terrible thing to go back to the drawing board, it’s just another step in the process. It’s even worse if you use a useless package and you don’t find the problem until it’s on the market.

The criteria for your beverage packaging choice

The right packaging – Criterion 1: Type of drink

Which kind of packaging is the best? It depends on the type of product in the first place.

People often forget that packaging has an important function. For example, protection functions, storage, and transportation functions. And information functions such as ingredients, sugar content, best date, barcode, or processing notification as well.

Whether it is milk, mineral water, lemonade, or juice, each beverage has its own packaging requirements. Milk beverage and beer suppliers can use dark packaging away from light since sunlight affects their quality.

Milk in glass bottles has been a tradition for centuries. It’s because milk is seen as the purest and most natural form of dairy product, which makes it stand out from other types.

So what’s the difference between fresh milk and packaged? Fresh, unprocessed dairy products often come in beverage cartons without an aluminum layer. Packaged milk requires this protective coating to maintain quality.

Drinks like beer, have special packaging requirements in most cases. As they contain carbon dioxide, none of these drinks can remain fresh in a composite carton. Lemonade, as another example, needs a stable size package to keep it carbonated.

The right packaging – Criterion 2: Transport route from bottler to consumer

For PET bottles, there are disposable and recyclable products. Among them, the wall of PET recyclable bottles is thicker than that of pet disposable bottles.

Environmentalists often vilify all forms of plastic.

But in fact, PET bottles have a better reputation for ecological balance. They’re lighter, so they save resources in production. And they save energy in transportation.

Therefore, the length of the transport route is a key factor in determining the sustainability of packaging.

Reusable versus disposable bottles for long-distance travel

The carbon footprint of a reusable water bottle is much lighter than that of pet or child-friendly disposables. For trips over 200 km, this can make all the difference.

Finally, the recyclable bottles must be returned to the bottling plant, which means twice the distance. For a reusable bottle, the key factor of ecological balance is not only the transport route. The number of cycles it takes also matters. For instance, a glass recyclable bottle can serve 15 to 20 times for a good life cycle assessment.

However, PET recyclable bottles should be cycled at least 8 to 10 times. The life cycle assessment of bottles with low cycle times is poor even if they are reusable.

The right packaging – Criterion 3: weight and shape

In fact, in Austria, the maximum weight of each truck loaded can reach 38 tons. The rule is that the lighter the package, the more liters the truck will carry. For example, a glass bottle weighs 500 grams, while a one-way PET bottle weighs only 25 grams!

If it’s a glass bottle, especially if the bottle is transported. For boxes, cans, and PET bottles, the most important thing is to bring the drink to the desired location. In this way, transportation efficiency is high.

Besides, the shape of the package also plays a role: conical glass bottles require more space than cans or beverage boxes.

In summary: The most important rules at a glance

The key factors determining whether one beverage package is more environmentally friendly than another are summarized as follows:

- Content: what properties must the packaging meet in terms of barrier performance and light protection?

- Compared with other packaging solutions, disposable glass bottles have obvious disadvantages because of their higher weight

- Recyclable pet disposable bottles often have advantages over reusable glass bottles

- The higher the recycled content in the packaging, the greater the impact on the environment

- Reusable bottles are appropriate if the transport distance between the filling plant and the consumer is low, e.g. for regional products

- The quality of disposable containers, especially the quality of bottle caps

- The high recycling rate of reusable containers

- Number of containers per truck

- Separate collection of disposable packaging.

What is the best choice for beverage packaging?

Honestly, the “best” packaging doesn’t exist.

And the sustainability of a packaging solution depends on many factors. The type of the drink, the distance of transport, and the weight of the packaging all matter.

So, the best choice for beverage packaging depends on what you want them to do.

Send us a message and tell us your needs, we will get you a suitable solution.

The trendy beverage packaging solutions

How to stand out in the saturated packaging industry?

These can be the common question of every beverage manufacturer.

At the same time, keeping up with fast-changing consumer demand makes the circumstance even harder.

Now, many large manufacturers launch new products regularly. But new product categories and products from small companies are breaking the status quo. Many companies make efforts to innovate packaging. By doing so, consumers will change their views of beverage categories, such as soda and beer. As a result, they may buy more beverages.

Smaller packaging sizes, many packaging, and situational packaging types are more and more popular.

Packaging innovation has become a way for beverage companies to meet the changing needs of consumers and attract them to buy. And it will continue to be a big trend in the industry.

Targeting millennials

Millennials are the most diverse generation in history. They’re always coming up with new ideas and expressing themselves freely, whether it be through social media or speaking out against something that needs to change. But don’t worry – there’s plenty you can do for this demographic! Studies show they prefer fresh food over processed options; buy them at grocery stores rather than fast-food restaurants because non packaged items won’t spoil as quickly on store shelves.

Packaging for convenience

The convenience of packaging is one of the selling points of food and beverage products. Consumers are more likely to buy portable, light products. Products that can be resealed or easy to open are popular, too. In conclusion, the convenience of packaging has a positive impact on consumer buying decisions.

Smaller sizes

Mini cans and bottles are one of the most important driving forces for packaging innovation. Coca-Cola and PepsiCo have reported a drop in sales of large packaged sodas.

By contrast, sales of smaller packages, such as 7.5-ounce mini cans and 8-ounce Mini bottles, have risen. At an earlier meeting, Sandy Douglas, President of Coca-Cola’s North America Division, said the packaging of smaller sizes would be a way for the company to reinvent its soda business in the next few years.

Why do soda companies need to reduce the scale of packaging? There are two main reasons.

The first one is to increase profits. It is inevitable to increase profits in exchange for convenience.

The other reason is that soda companies have to consider national soda tax proposals. The proposals from the World Health Organization, the Food and Drug Administration, and the 2015 dietary guidelines.

These proposals and guidelines require consumers to reduce sugar intake. Soda companies have to reduce the size of their packaging in order for consumers to cut back on sugar.

So, an 8-ounce can of coke is the perfect way to keep people’s coke at the ideal level. But “8-ounce” is not suitable for other drinks. It is only the perfect capacity for coke.

Reed also said that smaller packages are more common among large manufacturers than small soda ash producers. After all, large companies have the abundant capital capacity and strong production capacity. It is easier for large companies to change packaging flexibly.

At last, Reed said that large manufacturers are very good at understanding the needs of customers. They can always improve their packaging to meet the needs of customers.

Getting the right count

Major beer producers are experimenting with the number of individual products in multiple packages of different sizes.

They want to figure out the right number that can make the best use of the shelf space. They want to find out the right number of products for different retailers, such as grocery stores, drugstores, and convenience stores.

In fact, despite the number of products in multiple packages, manufacturers also change the price of multiple packages in different stores.

Reed said he could sell 15 bags at Walgreen and 12 bags at the grocery store. And the prices are different. There are many sales channels like these two.

Manufacturers are trying to learn the needs of different kinds of customers. They also try their best to find out the ideal price and the most popular packaging for different types of customers. They learn these for the sake of profit.

But actually, much of the packaging that the design is especially for retailers, like grocery stores. Different retailers need different packages and sizes.

The sampler packs

Sampler packages have appeared on the market, especially in the beer industry. According to Reed, the trend of sampler packages is more common among craft brewers than among major brewers. In fact, handmade wineries tend to produce several varieties.