All you need to know about paper packaging!

Manufacturers have made extensive use of paper-based packaging because it provides users with convenient storage and functional packaging that is both aesthetically pleasing and portable. In addition, this packaging is safe for the environment as it is made in a variety of shapes and sizes using recycled materials.

There is a reason why paper packaging (also known as paper containers) is more widely used and accepted than plastic containers, not only for the benefit of the end-user but also for the environment.

When it comes to paper packaging, did you know that there is actually a lot of variety? Different types and styles can be used for various businesses. For example in the UK or New Zealand food industry has different requirements depending on what they are storing! Reading this article about all things related with your business’s needs for proper labeling throughout production services will help ensure compliance with any new guidelines or laws introduced during current years – meaning no fines when importing products into these countries later down road.”

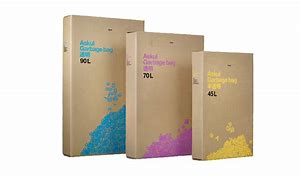

Kraft paper is strong and durable, making it perfect for the creation of packages. In 1882 a German named Carl found that by treating paper pulp with certain chemicals he could create more resilient types or packs than what previously existed in our world!

What is kraft packaging made of?

Like normal paper, the packaging is made of wood pulp, with an extra ingredient, sulfate, which increases the strength of the paper. In general, there are two major types of Kraft packaging. Type one: Coated unbleached Kraft (CUK), and type two coated recycled Board (CRB).

CUK paper packaging

CUK is an upgrade to the traditional, standard paper packaging that has been used for decades. It offers benefits like being thin and tear resistant while still maintaining stiffness which makes it perfect in all aspects!

CRB packaging

This Kraft packaging is made from recycled paper, which tends to make it a cheaper alternative to CUK paper packaging. However, it does have its downsides due to having less strength/tear resistance vs CUK however where strength/tear resistance problems are non-existent/low cause of concern CRB is a great way to save costs for your business!

Is Kraft packaging eco-friendly?

Kraft packaging is 100% eco-friendly. Kraft paper has the ability to create custom packaging that is both impressive and environmentally friendly. Business owners should consider using this material for their business's needs if they want a great first impression with customers while still minimizing waste! To sum up, Kraft packaging is a strong, eco-friendly package.

Main uses for Kraft packaging

You all see Kraft packaging designs on a daily basis. They are perfect for groceries, fast food restaurants, clothes bags, gift wrapping, hey you can even make your business cards out of them to give that extra strong message about your business commitment to the environment!

What is white cardboard?

Unlike paper, cardboard is thicker and can be easily shipped. It was invented in England as a way of storing products because it’s strong enough for this purpose without the need to protect its surface with an additional layer like kraft papers do which makes them bulky when compacted together or folded into thirds widthwise then fourthly stacked on top; however they still offer all these benefits while packing more efficiently into containers so you don’t have any wasted space!Cardboard also has the advantage of being able to be flat-packed and set up on site.

What is it used for?

White cardboard is used on a daily basis from everything to TV boxes, to storage to milk cartons. The use of cardboard is only limited to your imagination.

Is white cardboard environmentally friendly?

Cardboard like Kraft packaging is generally 100% biodegradable. There are however instances of cardboard not being completely environmentally friendly. The first instance is when a plastic or wax seal is layered on top which makes it harder to recycle. Another is like Kraft paper it becomes more environmentally friendly when the material is redistributed to the market via recycling.

What is coated paper?

Coated paper is paper which has a layer on top to stop liquids soaking in such as ink. This design choice can completely change the overall feel of the product.

Coated paper vs uncoated paper

Coated paper is what gives you that shiny, matte, glossy or semi-glossy feel to your design while uncoated paper is paper which allows liquids to soak in easier. You can think of it like the inside of a book as uncoated paper. while your milk carton is coated paper.

Is coated paper packaging recyclable?

Almost all paper nowadays is recyclable however coater paper packaging is generally more expensive to recycle especially if it is covered in plastic, aluminium, wax, gummed or anything similar. Thankfully in UK that magazine style coated paper package is able to be recycled though if you’re looking for a more environmentally concious option either cardboard or Kraft paper is the better option where possible.

About Offset paper

Offset paper is simply uncoated paper. It is the method of getting paint/ink onto uncoated paper packaging. It is the thinnest and simplest packaging of all 4 paper packages described in this article. Its major advantages are the cost and a generally higher consistency of image quality. It is more used for products such as envelopes, catalogs, newspapers, and so on. It can however be used in some cases for food packaging. Offset paper is also able to be recycled and can fully decompose.

What type of paper packaging is allowed for food in UK

Up above we have covered basic paper packaging, however, a large proportion of the packaging market goes to food. This industry has a lot of health and safety laws. In terms of what is allowed for food packaging in UK we need to look at FSA (Food Standards UK, responsible for food safety and food hygiene in England, Wales and Northern Ireland) for guidance. Specifically 4 chapters:

- Introduction and standards that apply to all foods

- Food Standards

- Food safety standards

- Primary production standards.

1. The food packaging must be safe

2. The packaging must be capable of being swallowed or obstructing any alimentary or respiratory passage

3. It must not cause bodily harm, distress, or discomfort if taken into the mouth

a) This standard also included moisture absorbers, mold inhibitors, oxygen absorbers, promotional materials, and writing/graphics in/on the package

4.This standard is applied to all food that is imported intended to be sold

5. Packaging used in contact with food does not cause the food to exceed permitted levels of metals, non-metals, or natural toxicants

6. Chemicals used to make food packaging should not present known hazards to the consumer

7. Packaging must comply with the maximum limits in food for carious food packaging chemicals

8. Packaging will not impact the safety and suitability of the contacted food

9. Recycled and reused materials may be used for food packaging applications provided they are suitable and won’t contaminate food

10. Packaging must be used which is fit for its intended use and only use materials not likely to contaminate food

UK and sustainable packaging

So we have covered the most common types of paper packaging, and current laws inside the UK but what makes packaging sustainable? For a complete detailing of everything your business needs to know about sustainable packaging we recommend reading this.Down below we have listed and briefly summarised the 10 points your business needs to be aware of when purchasing packaging.

What do businesses need to be aware of when designing and purchasing sustainable packaging?

There are a total of 10 major points your business needs to be aware of in order to create sustainable packaging. We have listed them down below.

1. Design for recovery

The UK has a goal for 2025 to significantly increase the number of recycled plastics and bioplastics used in packaging. By then, we will have an average 30% recycling material in our plastic packages – which means that whenever you buy anything from shopkeepers who are following these principles there will be extra benefits! Aka someone wants us all responsible consumers so when buying goods always ask yourself what happens after I use up this product? Is my package reusable? compostable?”, or recyclable?” You’ll want every part.

2. Optimise material efficiency;

This one is pretty straightforward. If the package can be made smaller, thinner, lighter, less wasted packaging without compromising the effectiveness/safety of the package then where possible do so.

3、Design to reduce product waste

Packaging plays an important role in the overall creation of your product. It can be defined two ways; how much waste is created from aspects such as poor quality or purchasing material for additional use when it isn’t needed? And also looking at what percentage gets wasted due to end consumers – eg food servings per packet so they don’t go to waste.

4. Eliminate hazardous materials

Simply put ensure the packaging you use avoids toxic/harmful substances to humans or other living organisms. Where they are unavoidable look at potential ways to reduce their impact/overall usage in the packaging. Your packaging needs to meet the UK and/or international standards such as the EU packaging and packaging waste directive. If the product needs to have some hazardous materials you will need to make sure it is labeled correctly to help with alternative collection/recycling programs.

Where possible use recycled materials. Consider adding a higher percentage of recycled content where possible without increasing the risk/function of the package to unacceptable levels. Overall add more recycled materials into the packaging supply chain where it is possible to do so.

6. Use renewable materials;

A renewable material is “Material that is composed of biomass from a living source and that can be continually replenished. Renewable materials include paper and cardboard from sustainably grown wood fiber, or a biopolymer from a sustainable source.” aka where possible use more renewable materials in your packaging.

7. Design to minimise litter

This requires you to know how and where your packaging will be used. Is it possible to reduce the overall amount of potential pieces of litter (think a plastic bottle has the container, lid, and wrapper)? It also requires adding advice on the correct disposal procedures.

8. Design for transport efficiency

This requires you to take into mind optimal transportation. This requires you to think about pallet, weight, how easy is the package design to recycle, the overall shape of the package design, transportation methods including loading and offloading.

9. Design for accessibility

Again a nice simple part of sustainable packaging. your design needs to be easy for consumers and retain its safety or quality. It should also consider what demographic it is aimed at so that they can better understand how their needs may differ from those of other demographics.

10. Provide consumer information on sustainability.

Your packaging needs to have clear labeling/advice on how to dispose of it in the greenest way possible. In addition, if possible it needs to consider the following points:

A. Environmental claims

B. Litter prevention

C. The UK recycling label if appropriate

D. Composting logo if appropriate

For more information on these points and how to follow them for your business check out the following PDF.

Work with the right packaging company

With all this information you can see it is really important to work with reliable packaging companies to make sure your paper packaging not only meets the UK standards but is eco-friendly, and sustainable. Primepac works with small to medium-large businesses to ensure their packaging is of a high quality design while ticking all the right boxes.

About Primepac

In an effort to meet the diverse needs of clients around the world, PrimePac offers creative packaging solutions that are tailored for each individual client. Our team brings together expertise from various fields including design and branding in order create fresh ideas with efficient processes while also catering specifically toward your target audience’s desires.

However, from our dedicated sales team and warehouse staff in the UK to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

Conclusion

In this article we have discussed the 4 major paper packages, what are the UK standards and how to ensure your packaging meets them. We have also covered the bases of what is sustainable packaging and what you can do as a business to help our environment. Check out ten Chinese factories where Primepac gets its supplies, or reach out today for more information on getting started!